Unit Injector

Technical condition requirements for removed injection units

1. The injection sprayers may be bent, broken or missing. 2. The injection unit may not be dismantled.3. The manufacturer's number (OE number) on the housing must be legible and comply with the catalogue number. 4. The housing and tightening (fixing) points must not be damaged. 5. The injector must not be heavily corroded or burnt (impairment of structure stability). 6. The injector must not be (or have), e.g. bent, twisted housing, broken pump spring, broken discharge pipe, etc.

Unacceptable examples

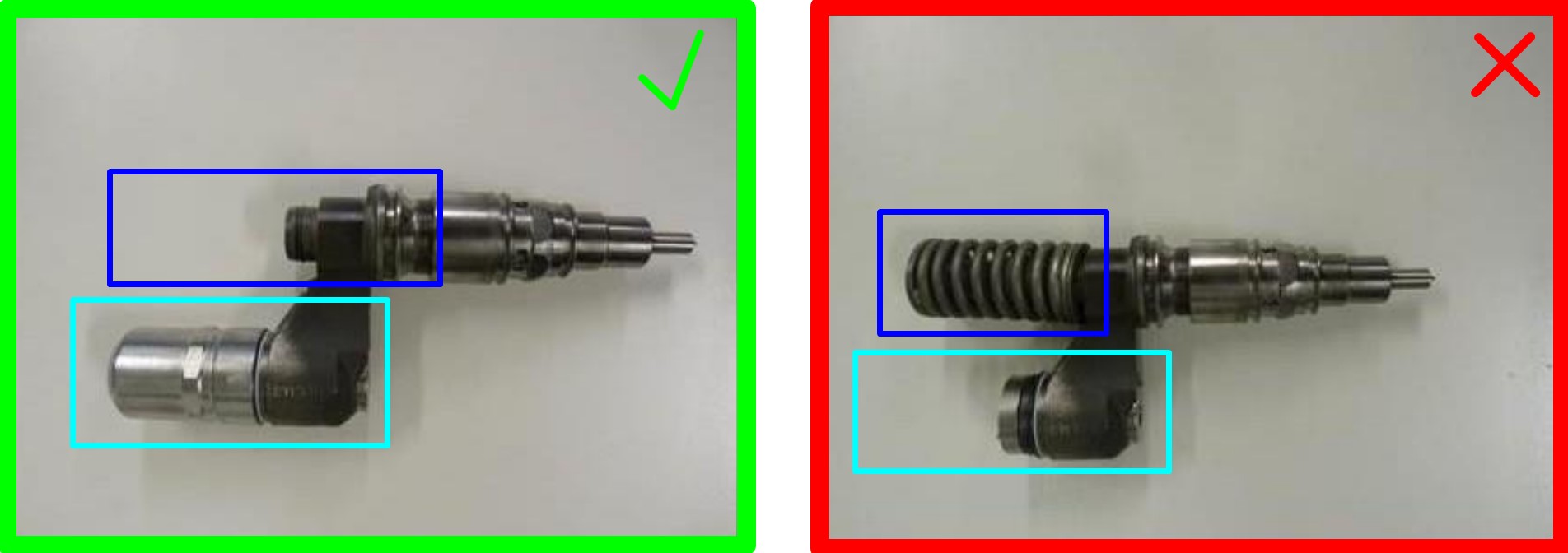

Component disassembled, loose screws - unacceptable

Component disassembled, loose spring - unacceptable

Incomplete core - unacceptable

Incomplete core - unacceptable

Incomplete core - unacceptable

Damage to the housing and nut - unacceptable

Damage to the spring plate bore, damage to the pump piston cover due to bolt breakage - unacceptable

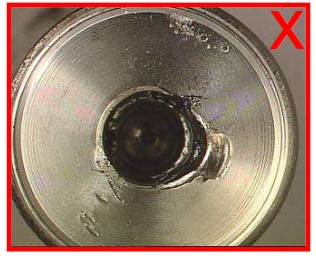

Damage to the electrical connection - acceptable

Damage to the collar and lid - acceptable

Discoloration due to the use of defective fuel - unacceptable

Permissible corrosion on the spring plate

Permissible corrosion on the spring

Permissible Corrosion on Atomizer

Permissible corrosion on flange and lid

Severe corrosion - unacceptable

No atomizer - acceptable; |##| Missing pin at the spring plate - acceptable

Slight corrosion without loss of material - acceptable

Mechanical damage. Damaged bolt and steel cover - acceptable

Unit Injector for trucks (all below)

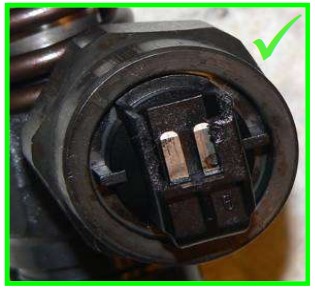

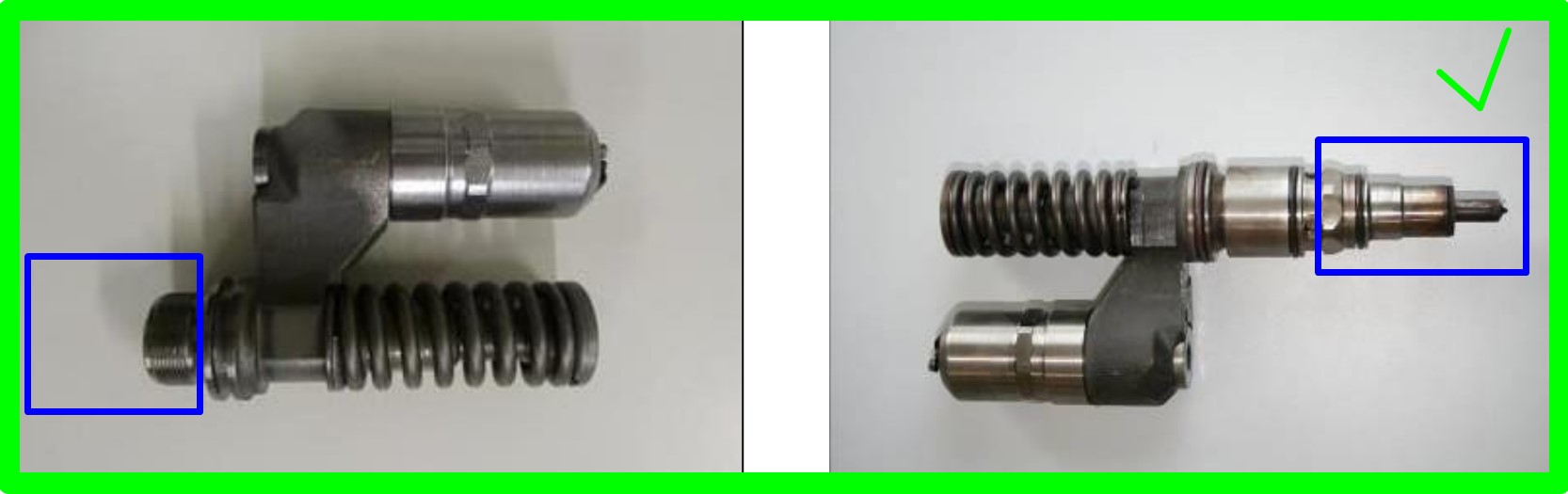

No spring - acceptable. |##| Disassembled unit injector - unacceptable

Damage to the brass cover - unacceptable

Language English

Language English Polski

Polski Deutsch

Deutsch Slovenský

Slovenský Latviešu

Latviešu Українська

Українська Magyar

Magyar Hrvatski

Hrvatski Lietuvių

Lietuvių Română

Română Český

Český Български

Български Italiano

Italiano Sporočilolovaščina

Sporočilolovaščina Русский

Русский Ελληνικά

Ελληνικά Eesti

Eesti Français

Français Nederlands

Nederlands