Truck Disc Brake Caliper

Technical condition requirements for removed truck brake callipers

1. Neither the brake calliper nor any of its internal components have been remanufactured by third parties (other than BPW).

2. The returned calliper shows little or no external corrosion.

3. The returned calliper shows little or no internal corrosion.

4. The returned clamp shows no or only minor mechanical damage.

5. The returned calliper was not dismantled (even partially). Guide bushings and seals are mounted on the calliper. The use of BPW spare parts kits (guide sleeves, seals and pressure pistons) is allowed.

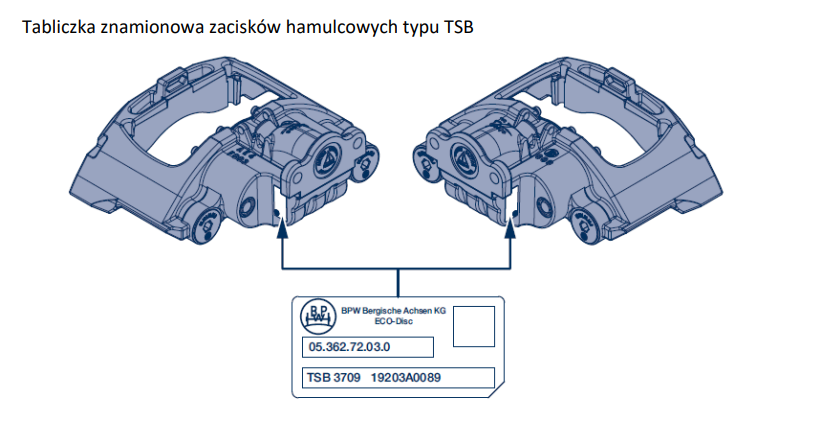

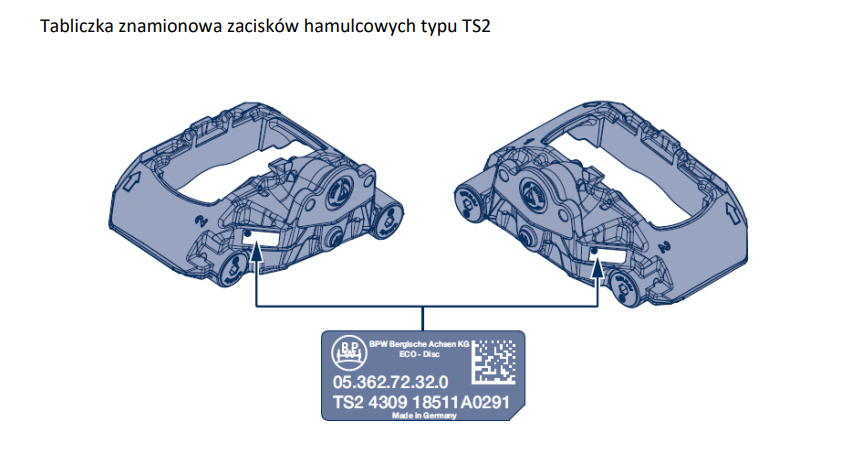

6. The returned clamp must be an original BPW product. Products from other manufacturers are not accepted.

Unacceptable examples

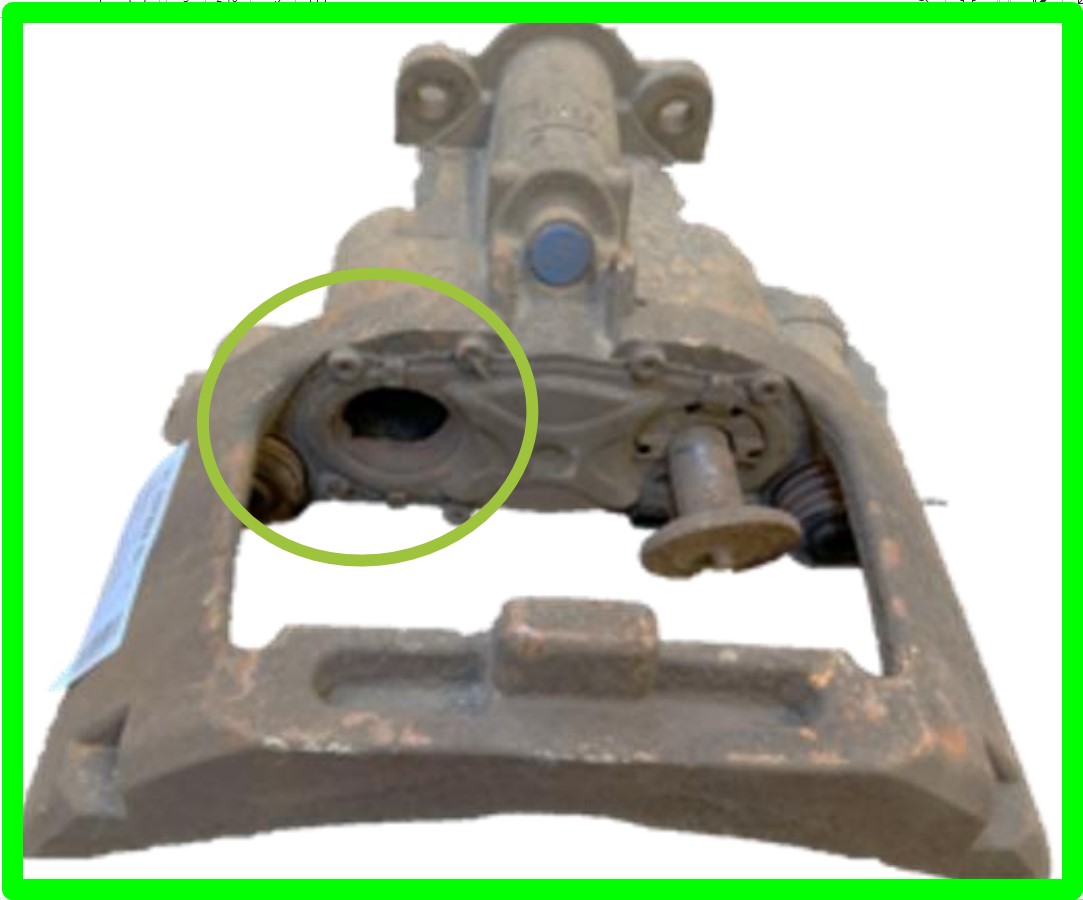

Bent Thrust Pads & Damaged Guard - Acceptable

Other elements after improper disassembly - unacceptable

Other elements after improper disassembly - unacceptable

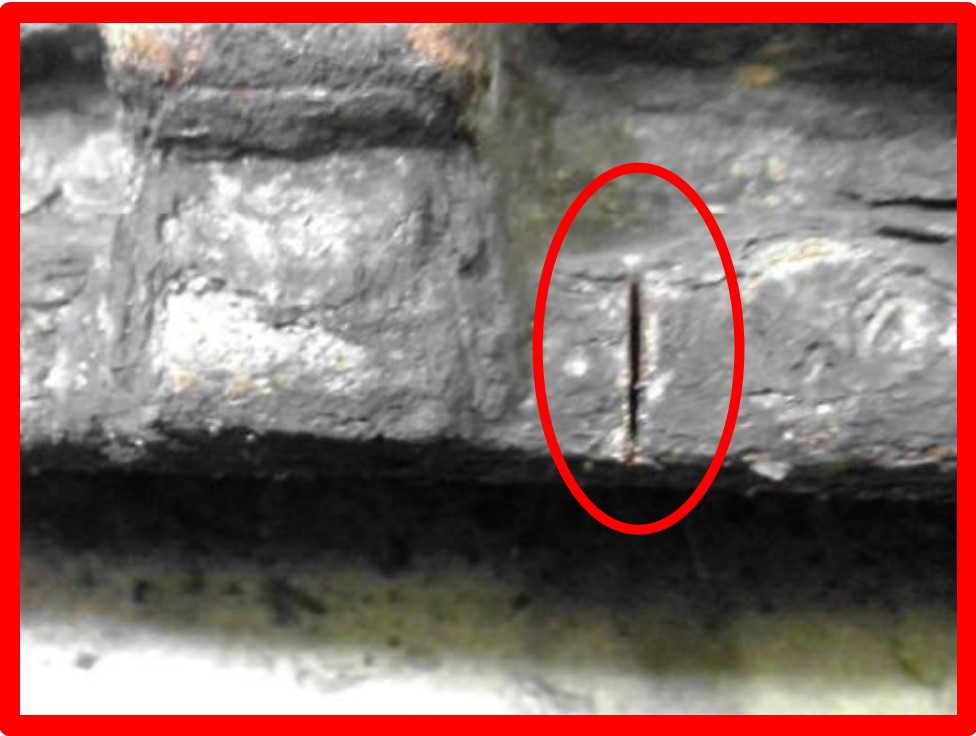

Cracks on the housing - unacceptable

Improperly worn brake pads - unacceptable

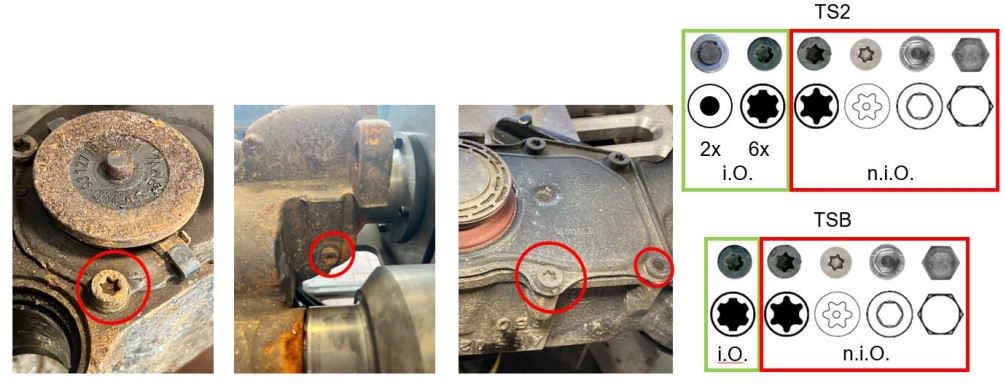

Damaged fasteners - unacceptable

Deep dents/abrasions due to mechanical wear and tear of the enclosure - unacceptable

Deep dents/abrasions due to mechanical wear and tear of the enclosure - unacceptable

Deep dents/abrasions due to mechanical wear and tear of the enclosure - unacceptable

Clamp incomplete - not acceptable

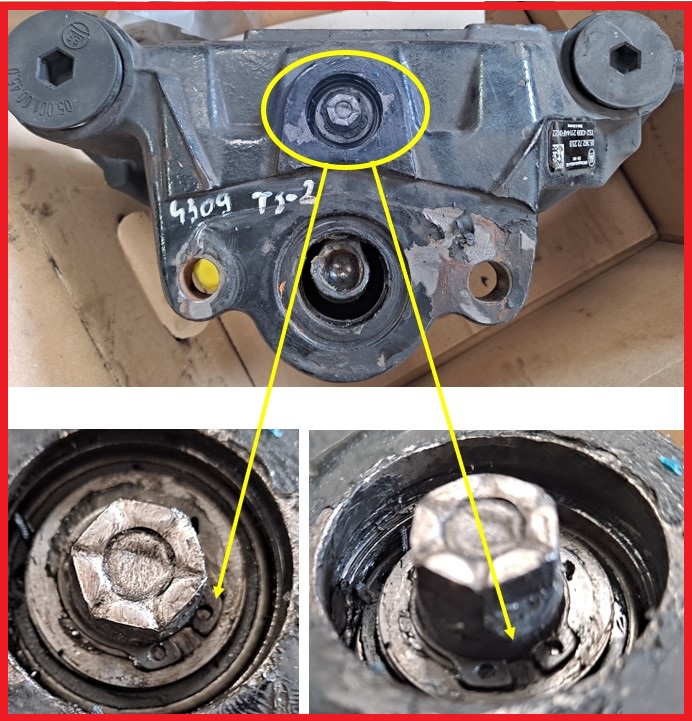

Deformation of the pin seat - unacceptable

Corrosion due to incorrect storage (not covered/no dry storage) is not acceptable. Corrosion due to use is acceptable

Only genuine cover plates are acceptable.

Only genuine bolt and locking bolt are acceptable.

Missing original markings and foreign screw locking – unacceptable

Only genuine BPW brake calipers are acceptable. Check screw head

Language English

Language English Polski

Polski Deutsch

Deutsch Slovenský

Slovenský Latviešu

Latviešu Українська

Українська Magyar

Magyar Hrvatski

Hrvatski Lietuvių

Lietuvių Română

Română Český

Český Български

Български Italiano

Italiano Sporočilolovaščina

Sporočilolovaščina Русский

Русский Ελληνικά

Ελληνικά Eesti

Eesti Français

Français Nederlands

Nederlands