Recirculator

Technical condition requirements for removed recirculators

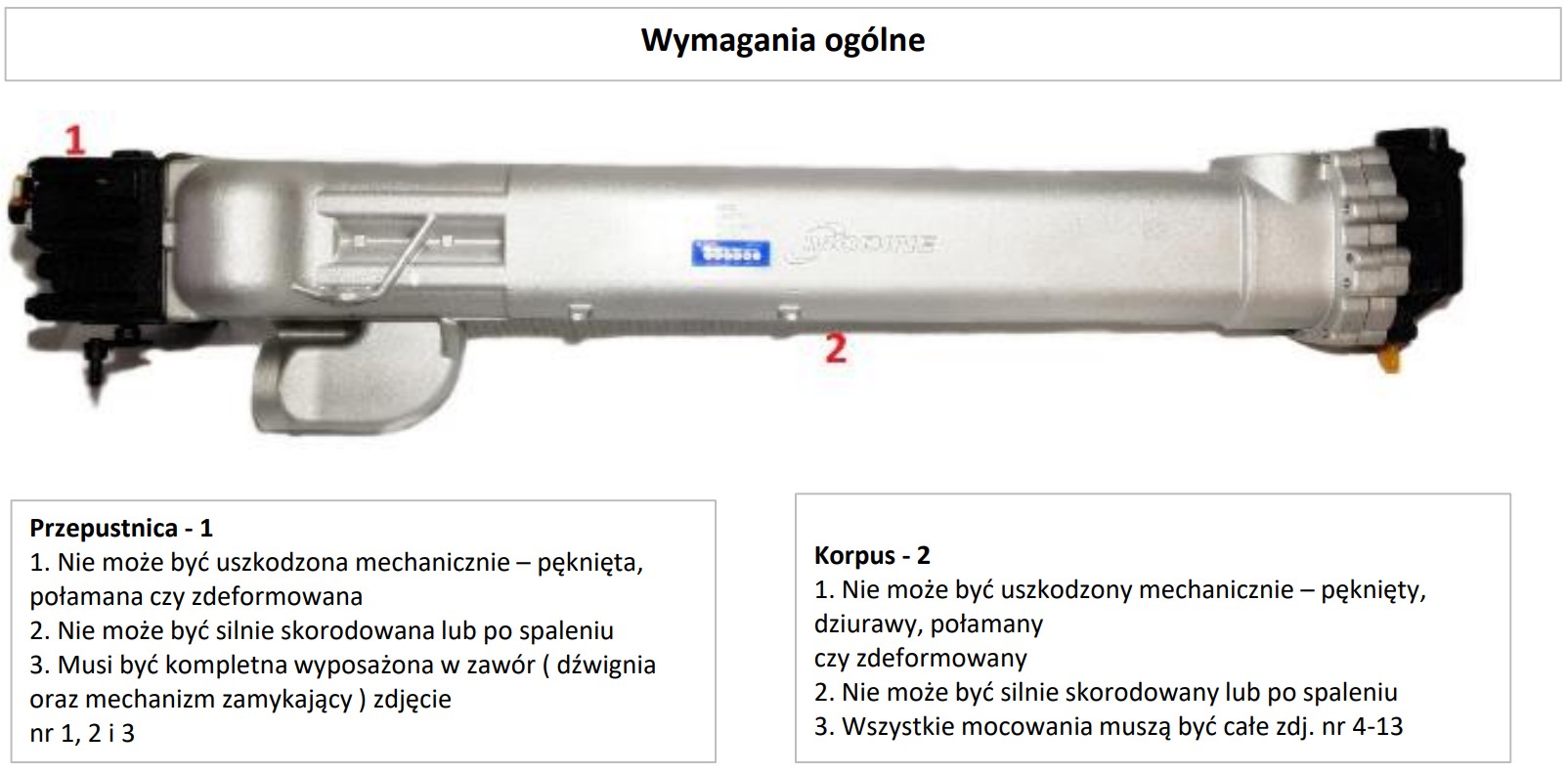

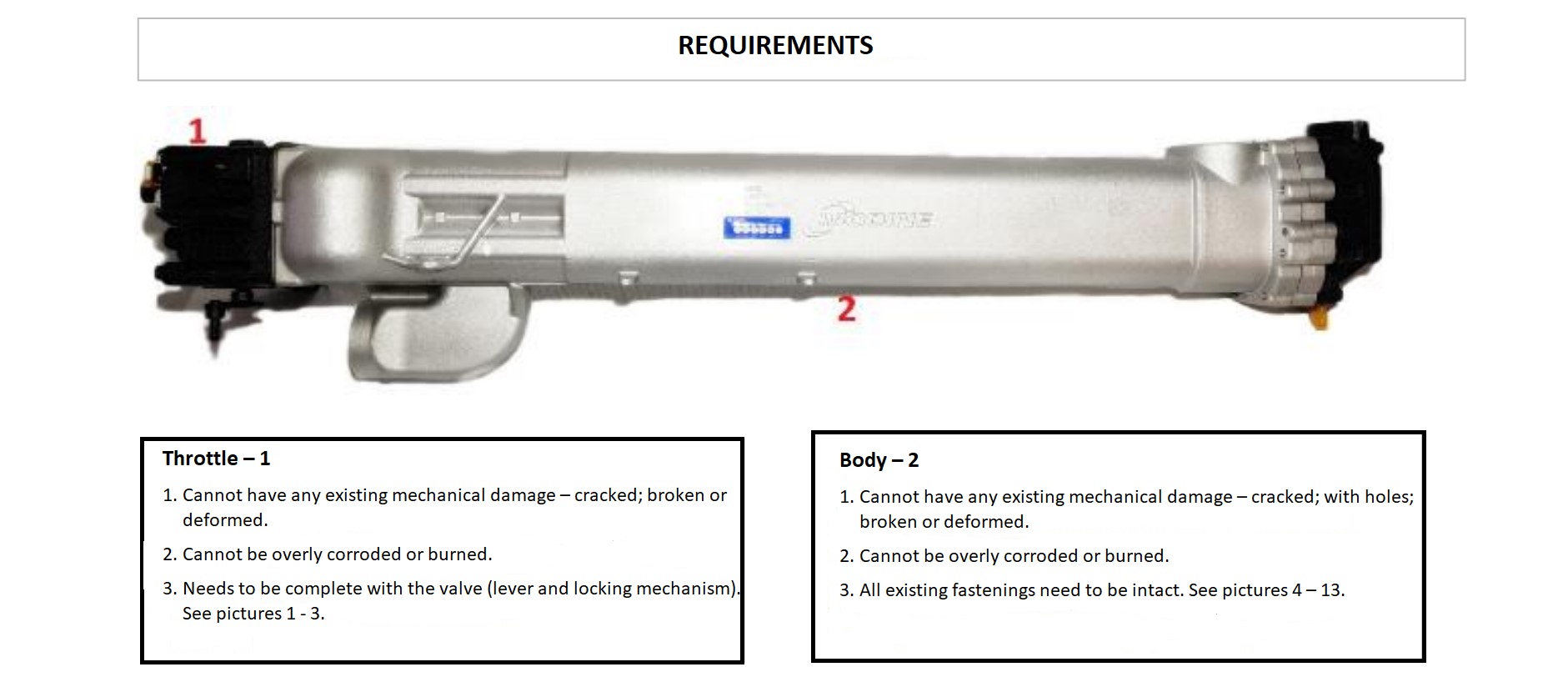

The basis for accepting the recirculator for reconditioning is its completeness (housing and throttle) and no mechanical damage.

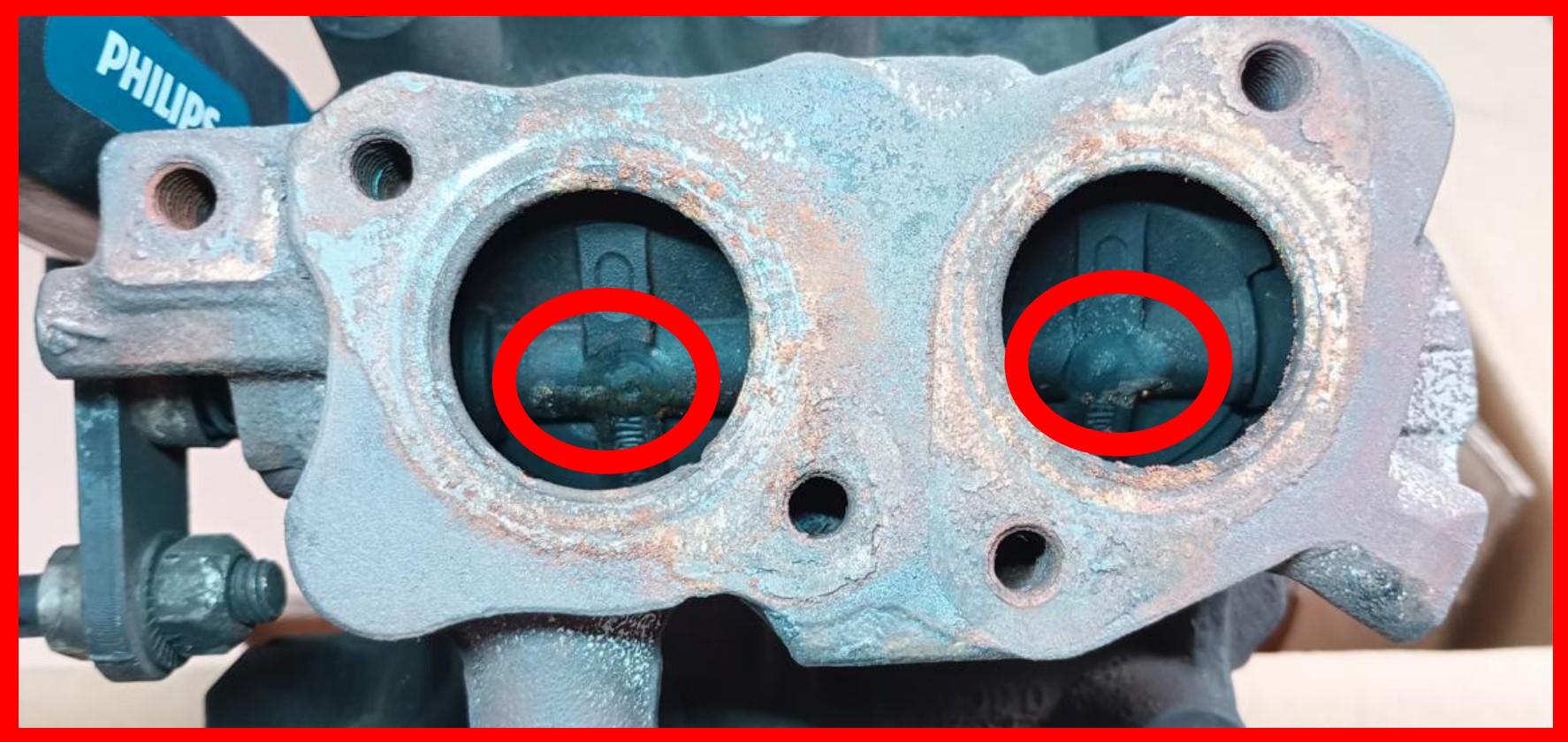

1. The recirculator must be carefully checked for cracks; missing (torn off) screw fastenings; holes; crosswise welds indicating additional repairs and pitting (made from corrosion).

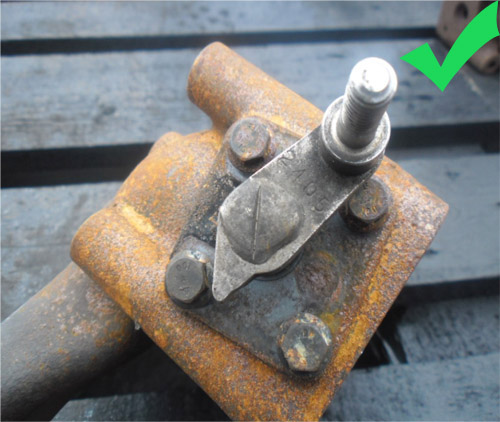

2. The throttle must be checked to see if the valve is present; moreover as written above, check for potential damages. The recirculator must be complete and not disassembled into its components.

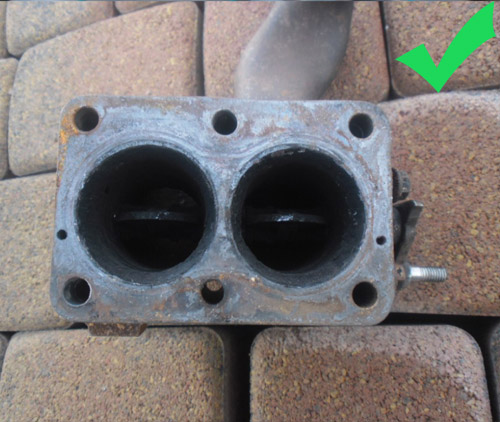

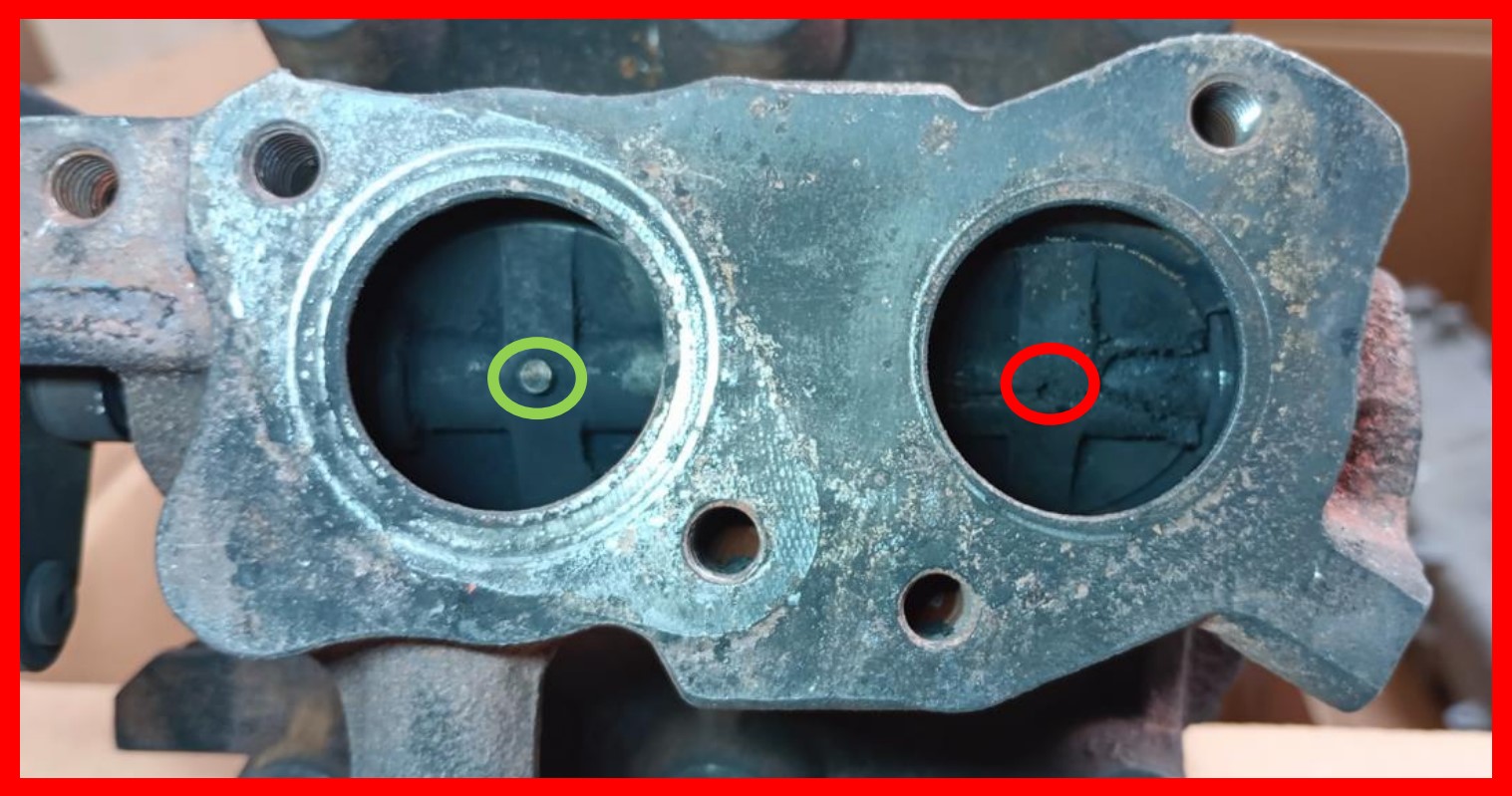

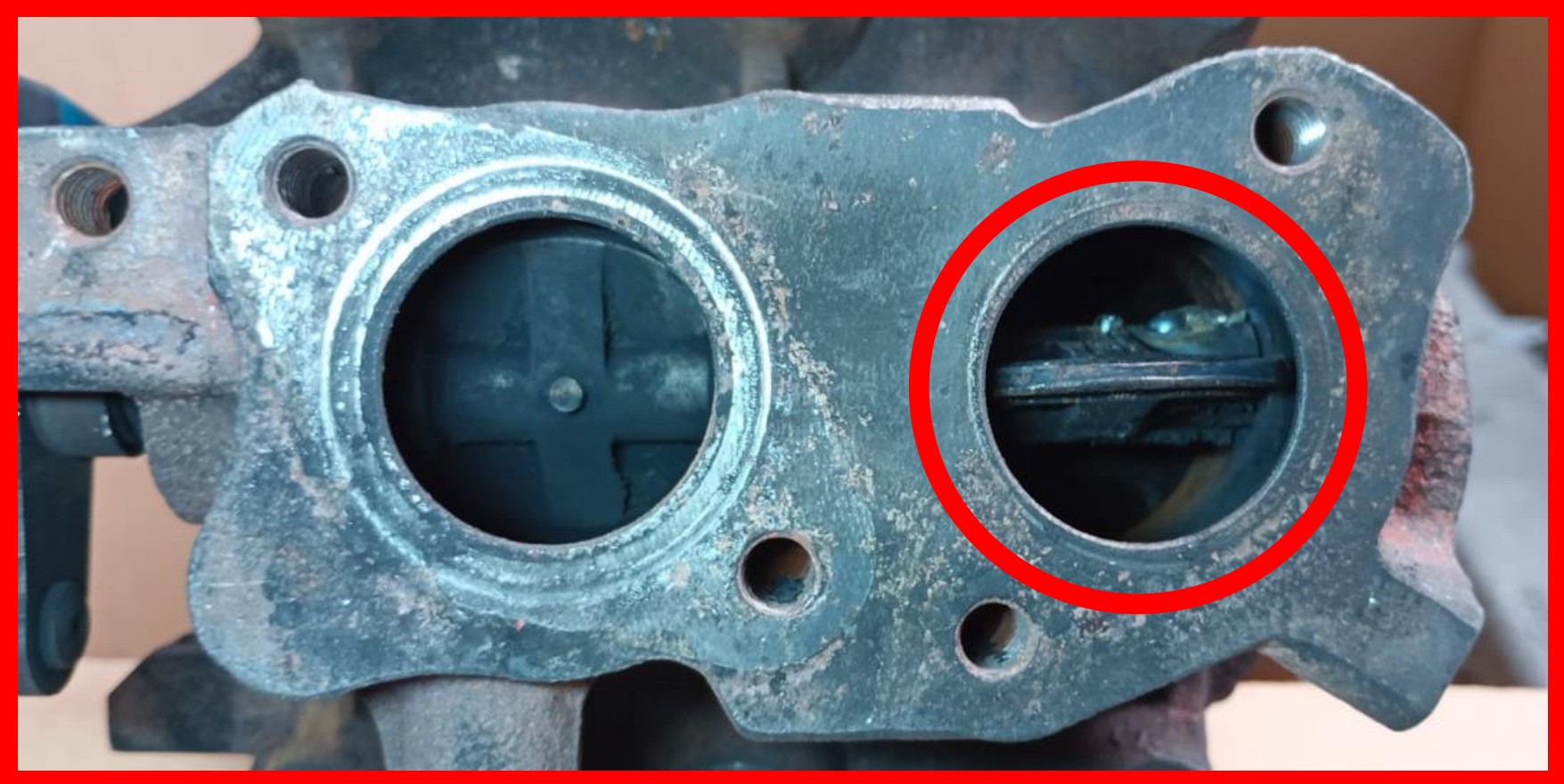

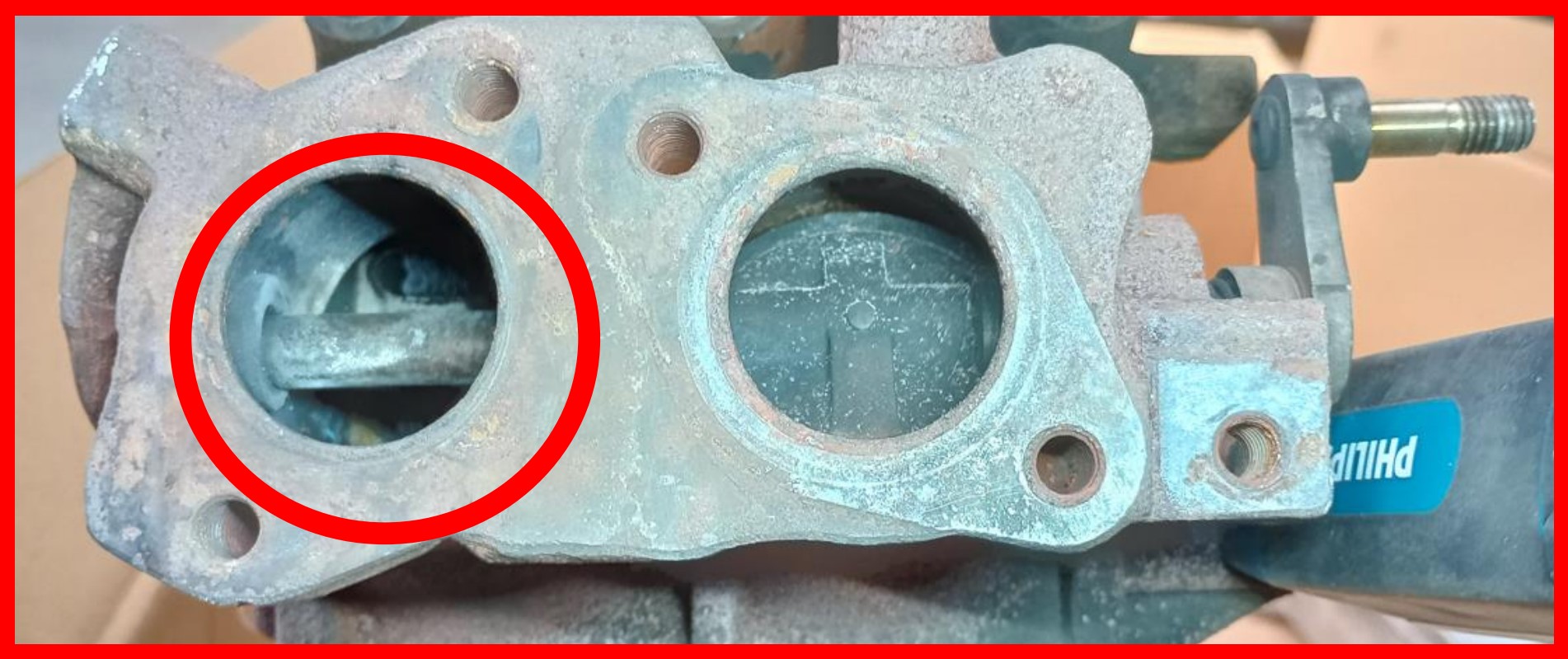

3. It is necessary to conduct a thorough inspection of the throttle flaps. They must be complete and original (the easiest way to tell is by the presence of rivets). The flaps should move evenly. Deviation of one of the flaps disqualifies the entire deposit (please see the images below, which should help you identify).

4. Cavities (slots) must be plugged (covered) in order to prevent any leakage of remaining liquids during transport. Moreover the core must be packed in the cardboard box after the new model and properly protected to prevent any damage.

Limbă Română

Limbă Română English

English Polski

Polski Deutsch

Deutsch Slovenský

Slovenský Latviešu

Latviešu Українська

Українська Magyar

Magyar Hrvatski

Hrvatski Lietuvių

Lietuvių Český

Český Български

Български Italiano

Italiano Sporočilolovaščina

Sporočilolovaščina Русский

Русский Ελληνικά

Ελληνικά Eesti

Eesti Français

Français Nederlands

Nederlands