Recirkuliatorius

Technical condition requirements for removed recirculators

The basic requirements for receiving the recirculator is its wholeness ( has to have complete body with throttle ) as well as no existing mechanical damage.

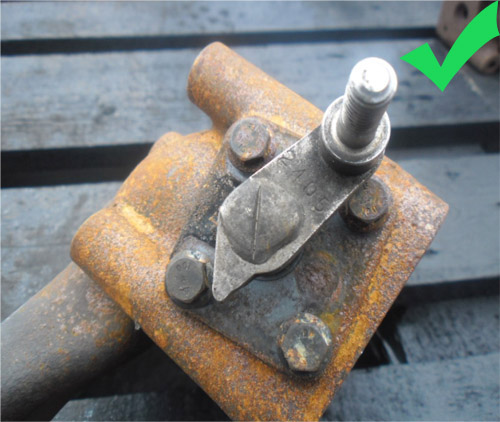

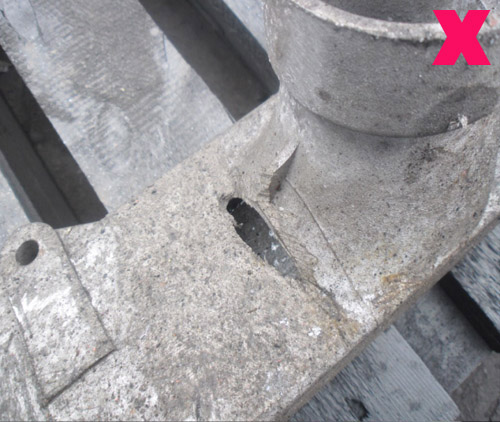

1. The recirculator needs to be well examined and thoroughly checked for any potential cracks; missing (torn) screw fastenings; holes; crosswise welds indicating added repairs; pitting (made from corrosion).

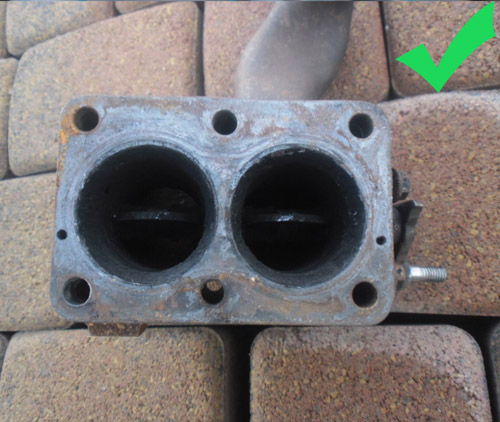

2. The throttle needs to be examined to check if the valve there is present; moreover as written above, check for potential damages. The recirculator needs to be complete as well as not broken down into components.

3. Cavities (slots) need to be plugged (covered) in order to prevent any leakage of the remaining liquids during transportation. Moreover the core needs to be packed in the box after the new model and properly protected to prevent any damage from happening.

It needs to be complete, and cannot be disassebled into parts.

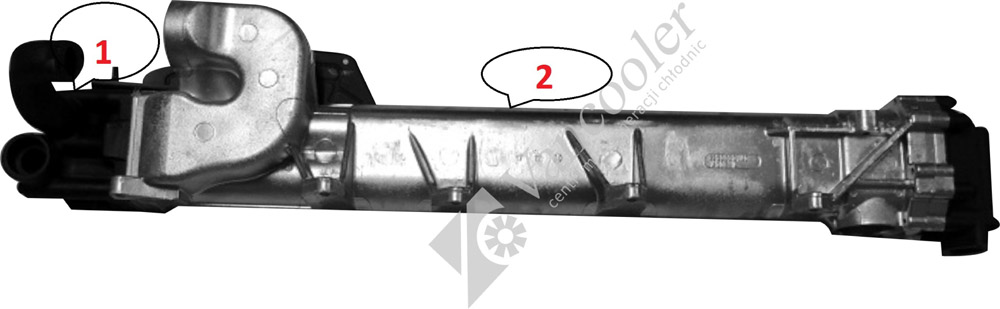

Throttle – 1

1. Cannot have any existing mechanical damage – cracked; broken or deformed.

2. Cannot be overly corroded or burned.

3. Needs to be complete with the valve ( lever and locking mechanism ).

Body – 2

1. Cannot have any existing mechanical damage – cracked; with holes; broken or deformed.

2. Cannot be overly corroded or burned.

3. All existing fastenings need to be intact.

Lietuvių kalba

Lietuvių kalba English

English Polski

Polski Deutsch

Deutsch Slovenský

Slovenský Latviešu

Latviešu Українська

Українська Magyar

Magyar Hrvatski

Hrvatski Română

Română Český

Český Български

Български Italiano

Italiano Sporočilolovaščina

Sporočilolovaščina Русский

Русский Ελληνικά

Ελληνικά Eesti

Eesti Français

Français Nederlands

Nederlands